Upplýsignar um ZCO Sjónaukana á Ensku af heimasíðu framleiðandans

WHY ARE ZCO-PRODUCTS SO SPECIAL AND UNIQUE

“Why do we use a 36mm Main Tube? Only two words are required to answer that question: “Uncompromised Performance”

Our passion, dedication, and complete focus is building nothing but the highest quality rifle scopes. This is only accomplished with the most modern and technologically advanced optical and mechanical designs. At 37.9 ounces, the ZC527 is still one of the lightest weight rifle scopes in its class.

Our 36mm main tube allows us to deliver major performance gains both optically and mechanically. Historically, one of these systems is compromised in favor of the other. This compromise is non-existent in ZCO rifle scopes. Larger internal lens elements in critical positions yield the highest level of optical and mechanical performance in the industry. An incredible 35 mils of usable elevation and 20 mils of windage adjustment is available while maintaining consistent click value and reticle subtension.

The 36mm main tube allows additional internal room to isolate and protect the optical components to withstand external distortion, stress, and impacts. This results in the most stable and consistent optical and mechanical performance to maintain point of impact under a wide variety of environmental extremes. Our design is also stronger in critical junctions and mechanical areas due to a thicker cross section in specific areas. The scope body is essentially an exoskeleton providing the foundation for the optical and mechanical components to come together, and ZCO goes to great lengths to build the strongest and most stable scope bodies in the industry. Every ZCO rifle scope body starts as a solid aluminum billet that is fully CNC machined and stress relieved multiple times throughout the machining process, virtually eliminating stress or “memory” in the scope body. Our machining process ensures your point of impact remains unchanged from moderate to extreme temperature fluctuations.

“Optics – The rifle scope is the human interface to the target, so the very best target image is required.”

Every scope is a compromise between optical performance and mechanical capability. ZCO´s 36mm main tube design yields outstanding optical performance with no compromises to the mechanical system.

ZCO utilizes European Schott lenses. Schott is renowned for superior quality lenses and they deliver the highest quality on the most consistent basis with the latest lens technology available. We utilize their Extra-low Dispersion (ED) lenses for the objective elements to maximize resolution, color correction, and contrast. Larger lens elements in critical positions achieve the best in resolution, light transmission, and flatness of field. Like our lenses and optical design, our lens coatings utilize the latest advancements for ultimate performance.

In recent years, significant advancements in eyepiece lens design have greatly expanded optical performance. ZCO is employing these advancements with a new industry leading eyepiece design that delivers maximum field of view (FOV), a substantial eye box, eye relief, and flatness of field. The overall image perception and ease of use produce the highest level of shooter comfort and less eye strain to reduce shooter fatigue during all day use. The 5X and 6x zoom ratios combined with an exceptionally large FOV and a wide parallax adjustment range from 25 meters to infinity make our rifle scopes the best suited for numerous shooting applications. These design traits give first-rate versatility and flexibility for faster target acquisition in demanding field shooting positions, faster shot recovery, and overall usability no matter the shot distance. The FOV is 28.0’ – 6.0’ (4-20X) or 21.0’ – 4.5’ (5-27X) making these rifle scopes among the widest offered FOV available from any similar configuration.

In ZCO rifle scopes, every single lens is carefully scrutinized to ensure very stringent quality control is maintained. Unlike many other companies, extra care and attention is given to the Refractive Index (RI) which is a critical specification. If the RI is not held to tight and specific tolerances, inconsistent click values and reticle subtension will manifest in the scope as well as degrade optical performance. In order to achieve the finest in optical quality, we go through a painstaking process of optically indexing our lenses on every rifle scope we build. Optical Indexing is a time consuming hands-on process that delivers the highest level of performance and consistency from one scope to the next and ultimate product quality control.

We further secure our lenses with an innovative Center Lock System (CLS) for each lens element and then permanently bond the lens inside the mechanical housing with an advanced epoxy UV bonding agent. The CLS automatically centers the lens and holds it absolutely concentric and secure with negligible stress. The result is every optical element is retained by the most solid and stable method with near zero stress thereby delivering maximum durability. Our method is proven, this is simply the most consistent and stable way to mount the optical elements.

A Magnification Change Lever (MCL) is machined into the magnification ring where it is ergonomic, snag free, will not hinder bolt manipulation, and is fast to manipulate even in cold weather. ZCO gives great consideration to rotational torque of all controls, so rapid changes of any control is possible with smooth and consistent torque even in freezing cold weather. As an added benefit, the magnification ring is slightly raised and angled toward the shooter. As with all of the engraving, the numbers are enlarged for easy reference of the magnification setting from shooting position.

A fast focus locking diopter adjustment allows for precise reticle focus and ensures the diopter setting never changes unintentionally. Most shooters utilize flip up lens covers which tend to inadvertently get pushed around and change the diopter setting when they are open. Our diopter will positively lock, is easy to secure yet disengage, and it accepts top quality Tenebraex® lens covers without an additional adapter.

When every other aspect of your rifle and ammunition is held to the highest of standards, shouldn’t your scope’s mechanical system do the same?

ZCO uses all new construction techniques and methodologies. We test our designs under the most demanding conditions while holding the most stringent standards in the industry. We hold ourselves to the highest standard so our customers don’t have to.

At the heart of our mechanical system is an extremely robust erector return spring. Exhaustive testing was performed on multiple spring styles and materials and we have found the absolute best and most consistent spring to deliver unmatched reliability. Our main spring is significantly larger, more durable, and produces the best consistency throughout and beyond its operational range than has ever been included in any other scope on the market.

Our elevation and windage turrets are deliberately designed and engineered with advanced component specific materials to provide ultimate consistency and accuracy for a lifetime of unfailing performance. The elevation and windage click spline mechanisms use hardened steel that is eroded cut for the utmost in precision. Using the hardest materials in these critical components is vital. The eroded cut process allows us to maintain the highest levels of precision and precise tolerances that broaching, casting, or extrusions of softer and inferior materials just don’t deliver. The end result is the most accurate method for producing precise click value accuracy, longevity, consistency, click feel and visual alignment for the user that will not wear out under severe and constant cycling.

All other areas of our rifle scopes use either hardened steel, aluminum alloys, or a silicon bronze alloy specially selected for its wear resistance and natural lubricity creating the perfect combination for critical interfaces. Every component material was analyzed for its specific application and selected to provide our end goal of Uncompromised Performance!

ZCO threaded components of the elevation and windage adjustments are hand assembled through a swaging and burnishing process which results in the tightest possible hand mated fit of the thread engagement. This technique has been exhaustively tested for thousands of rotations and proven to deliver the pinnacle of performance and accuracy in this critical interface.

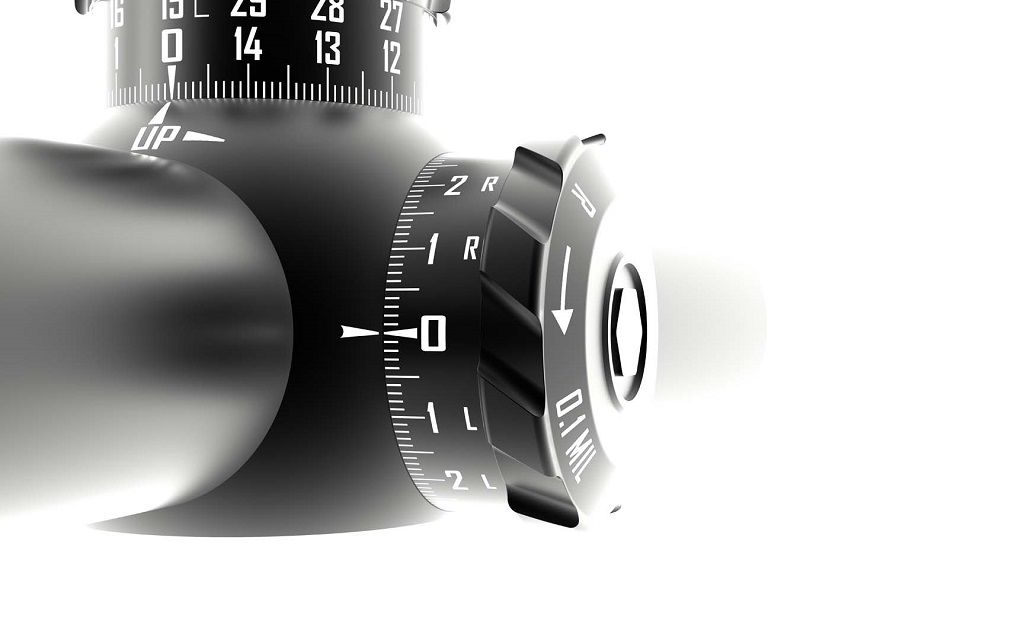

An unprecedented 35 mils of internal elevation travel in 2.25 turns along with 20 mils of windage adjustment sets an all new high in this class of rifle scope. An internal Return 2 Zero (R2Z) feature is built into the elevation turret and allows 0.5 mils below the zero point. A rotation indicator sits flush with the top of the elevation turret and automatically extends upward as the turret goes into the second rotation. A single white band is visible on the indicator giving a visual as well as tactile confirmation of the second rotation of the turret. The indicator extends up further on the third rotation and displays a separate double white band. Our indicator is easily seen and felt keeping you situationally aware of your current elevation setting.

The turrets on ZCO rifle scopes are a low-profile wide-diameter design making them highly streamlined with wide click spacing for faster visual identification as well as being easy to grasp with wet or cold hands or under stress. All of the external components are machined on 5 axis CNC machining centers. These state-of-the-art machines only produce one part at a time which may increase time and cost, but but also increases overall quality. The click and number engravings have been maximized to offer rapid visibility and identification specifically for aging eyes which also makes it extremely easy for the younger eyes. For example, the 0.1 mil click markings along with the engraved numbers are among the largest in the industry and specifically designed for fast and easy distinction. Our elevation and windage adjustments also integrate an intuitive and simple push/pull locking mechanism. This mechanism has explicit engineering for smooth and positive operation throughout the range of travel, giving the user peace of mind that the adjustments never move when not intentionally doing so.

Parallax compensation adjusts to 25 meters and out to infinity. This means our rifle scopes are perfectly suited for everything from indoor small bore rifle competition or Extreme Long Range applications. Our parallax adjustment has an excellent balance of speed and precision making it quick, accurate, and naturally easy to establish a parallax free image even under heavy mirage or other challenging conditions. ZCO delivers an unmatched combination between mechanical and optical shooter interface, quickly and easily eliminating parallax.

A ZCO exclusive Automatic Illumination Management™ (AIM™) is located with the parallax turret where it is easy to activate yet maintains a streamlined design. Our illumination control doesn’t hinder viewing of the turrets or take up precious ring mounting space on the main tube. The AIM offers advanced features never before brought together in this style of rifle scope. A digital Illumination rheostat system is utilized and color is user selectable for red or green. A standby mode is activated when no motion of the rifle scope is detected for three minutes but immediately comes back on when the rifle scope is moved. An auto-off mode is activated when no motion is detected for two hours thereby saving your battery life. Simply turn the illumination dial back to the OFF position to reset the electronics and then adjust illumination intensity to the desired level. Additionally, illumination is deactivated by the AIM when the scope exceeds 75 degrees in up or down angle tilt or when exceeding 45 degrees in roll to either side. All of these features result in significant conservation of battery life meaning fewer battery replacements and an optic you can count on when reticle illumination is required.

Reviews

There are no reviews yet.